|

Boilers And

Burners

Comprehensive CFD Simulation

of the

Combustion

Chamber of

SHAZAND Power

Plant Boiler

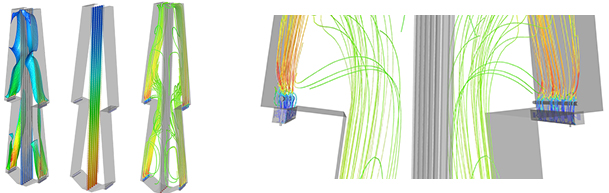

This project

was performed in

2012 with the

goal of

comprehensive

analysis,

including CFD

simulation of

combustion and

pollution for

boiler

combustion

chamber in

different

operating

conditions. This

325 MW boiler

has a front and

rear walls each

include 12

burners. At the

first step wind

box was

simulated. Using

wind box

simulations the

static pressure

for each 24

burners due to

non-uniform

distribution of

air was

specified. Then

with a precise

model and mesh

generation of

burners, the

percent of air

distribution in

primary,

secondary and

tertiary airways

was specified.

With the air

mass flow rate

for each burner

and the

percentage of

distribution in

each airways,

including burner

guide vanes, a

comprehensive CFD simulation

for combustion

chamber was

executed. Based

on studies the

effect of

different

operating

parameters such

as GR fan was

specified. After

a complete

study, various

strategies for

air pollution

reduction and

combustion

chamber

optimization

were carried out

and a deep

insight into

boiler design

and optimization

was produced in

Arya Alborz

Company.

|

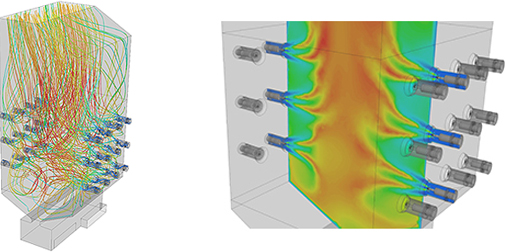

Comprehensive CFD Simulation

of SHAZAND Power

Plant Burners

This project was

performed in

2012 to specify

the percentage

of air

distribution in

primary,

secondary and

tertiary airways

in a burner. At

first step a 3D

model of burner

was created and

a proper mesh

was generated.

Then using CFD

simulations the

combustion and

air distribution

in different

airways at

various inlet

static pressures

were carried

out. These

simulations were

executed as a

primary step for

a precise and

comprehensive

simulation of a

325 MW boiler

combustion

chamber.

|

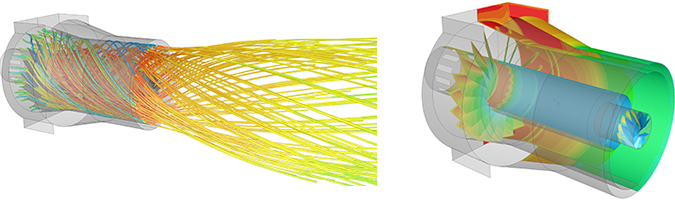

Comprehensive CFD Simulation

of a 325 MW

SHAZAND Boiler

Wind Box

This project was

performed in

2012 to specify

the air

distribution and

static pressure

at the inlet of

each 24 burners.

After a 3D

modeling and

mesh generation,

air flow

distribution was

simulated. Based

on aerodynamic

design of ducts,

significant

non-uniformity

of air flow

distribution

(300%) in 24

burners was

observed. The

lack of

formation of the

stoichiometric

combustion,

results in the

production of

air pollution.

Also increasing

the air flow

rate leads to an

increase in

flame length in

some burners,

flame

inclination

towards some

water walls and

resulting in

overheating,

burning and

destruction of

the water walls.

Due to the poor

design of wind

box,

optimization for

resolving the

problems was

carried out with

Arya Alborz

engineering

group.

|

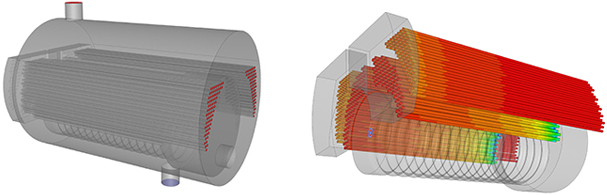

Comprehensive CFD Simulation

of a Three pass

Fire Tube Boiler

This project was

performed with

the aim of

simulation and

optimization of

a three pass

fire tube boiler

in 2013. At

first step the

geometry of a

three pass fire

tube boiler with

a capacity of

25,000 lbs/hr

was created.

After the 3D

modeling a

professional

mesh was

generated. Then

by applying the

air and fuel

mass flow rates

as inlet

boundary

conditions,

fluid flow and

combustion were

simulated. Using

precise CFD

simulations the

percentage of

convection and

radiation heat

transfer in

first, second

and third pass

of boiler were

specified. In

second step the

optimization for

higher

performance was

provided.

|

Comprehensive CFD Simulation

of a Steam

Reforming

Reactor at

TEHRAN Refinery

This project was

performed in

2006 for a

complete

performance

analysis of the

reactor and to

specify the

optimum

condition for

burner

combustion.

Generally,

hydrogen is used

in various

industries for

reduction. For

hydrogen

production in

refineries,

water vapor and

methane, flow in

tubes filled

with catalysts.

The heat is

transferred from

outside of tubes

from the flame

formed by

combustion of

gas in a counter

flow manner. The

formation of

chemical

reactions inside

the reactor is

so important.

Heat transfer

reduction to the

feed, reduces

the reactor

performance and

flame length

extension can

lead to bending

and deformation

of the reactor

tubes. Due to 12

meters height of

reactor, pipes

replacement

requires unit

shut down and

imposition of

heavy costs. As

target of this

project the fuel

and air ratio

and mass flow

rates were

adjusted to

efficiently

transfer the

heat for desired

chemical

reaction inside

the reactor and

to prevent the

pipe bending and

destructions.

|

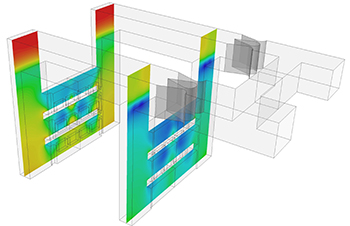

Combustion

Simulation Using CFD Techniques

in a Gas Heater

This project was

performed in

2003 to study

the effect of

geometric

parameters on

the performance

of a gas heater

for

optimization.

After 3D

modeling and

mesh generation,

flow

distribution and

combustion were

simulated and

the effect of

geometric

parameters for

optimization was

carried out.

|