|

Equipment

Cooling and

Industrial

Ventilation

Design

and Construction

of Internal Fans

for Cooling

System of a

Three Phase

Induction

Electric Motor

Using CFD

Simulations

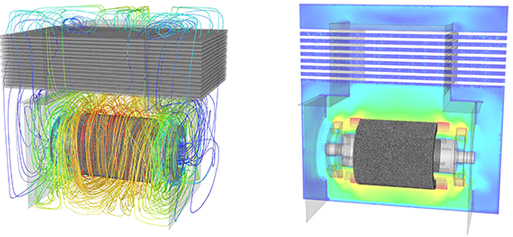

This project was

performed in

2014 to modify

the cooling

system of a

three phase 2 MW

induction

electric motor

for full load

operation during

summer. At the

first step the

geometrical

characteristics

such as the size

of the rotor,

stator, inner

ducts and

geometric

details of fans

and heat

exchanger were

extracted. After

a complete 3D

geometric

modeling of

electric motor,

fine mesh using

34 million

elements was

generated and a

comprehensive

thermo-fluid

analysis was

performed.

Because of

electric motor

heat flux

variation with

loads, coupled

simulation

between heat

exchanger and

electric motor

must be

executed.

Through deep

insight observed

using CFD

simulations of

flow

distribution and

heat transfer in

heat exchanger

and electric

motor,

sensitivity

analysis of

different part

modifications

such as cold

fan, hot fans

and heat

exchanger were

specified.

Finally new fans

were designed

and constructed

for cooling

system retrofit.

|

Design

and Construction

of Cooling

System for

Dynamometer Test

of a Wankel

Engine Using CFD

Simulation

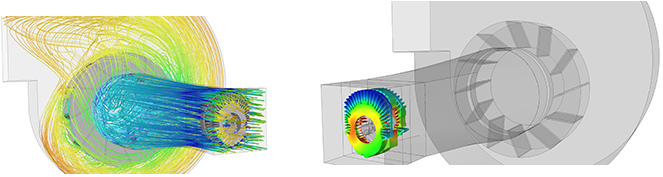

This project was

performed in

2012 with the

aim of design

and construction

of a cooling

system for

dynamometer test

of an air cooled

wankel engine.

At the first

step a precise

3D model of the

engine with

cooling fins was

created. Then

because of heat

transfer

sensitivity to

mesh size,

professional

mesh was

generated for

engine and

domain. With

specifying the

performance of

the engine and

fuel

consumption,

engine heat flux

was found out.

Using the

maximum heat

flux, the

required air

flow speed for

cooling was

specified. Then

fan and duct

were designed

using numerical

simulations.

Finally the fan

and duct were

constructed and

operational

tests of cooling

system had quite

well agreement

with CFD

simulation

results.

|

Knowledge

of Transformer

Room Ventilation

Design provision

Using CFD

Techniques

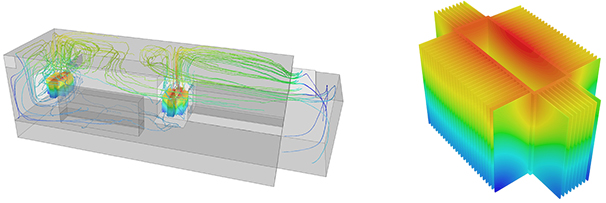

This project was

performed in

2010 with the

aim of

transformer room

ventilation

design knowledge

production. At

the first step a

comprehensive

measurement from

40 transformer

rooms including

the air

temperature,

inside room air

temperature,

transformers

surface

temperature,

room size,

cooling area and

the arrangements

was done. At the

second step a

sensitivity

analysis of

different

parameters was

studied. After a

deep insight

into ventilation

using CFD simulations,

a comprehensive

design criteria

for transformer

rooms

ventilation with

one or two

transformers

with the power

of 630, 800,

1000,1250 and

1600 KVA for

on-ground or

under-ground was

produced.

According to the

simplicity of

the standards

and the

dependency of

ventilation

design to

geometric

parameters, this

project

developed a deep

insight through

the industrial

ventilation

design in Arya

Alborz Company.

|

Piston

Effect

Phenomenon Study

Using CFD

Simulations in

Subway

Ventilation

Design

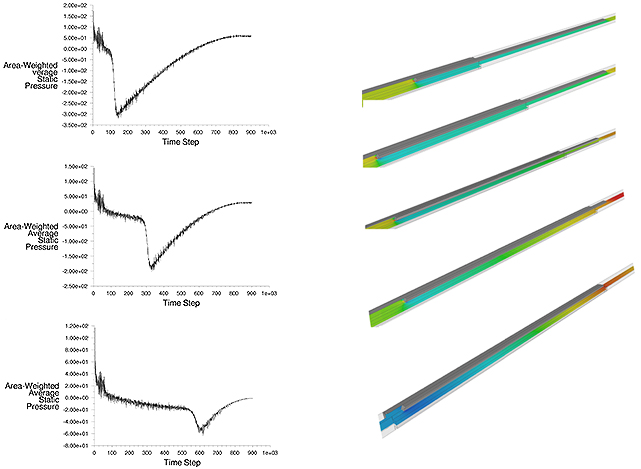

This project was

performed in

2010 with the aim of

subway stations

ventilation

design and

optimization

using CFD

simulations.

Subway movement

in tunnels can

cause the

blowing and

suction of air

from ventilation

ducts. One of

the most widely

used software

for subway

ventilation

design is SES.

SES software

uses empirical

correlations for

linear

ventilation

design of

stations. Today,

with the

improvements in

hardware and

software

industries, CFD

analysis can be

used for

ventilation

design and also

to exert the

piston effect of

other stations

using Dynamic

mesh

simulations.

With the

unsteady

simulation of

train movement,

the static

pressure

fluctuations

were specified

in the stations

and the

knowledge of

piston effect

phenomenon for

subway

ventilation was

developed in

Arya Alborz

Company based on

numerous CFD

simulations.

|

Ventilation

Study of a Road

Tunnel Using CFD

Simulations

This project was

performed in

Arya Alborz

Company to

produce the

knowledge of

road tunnel

ventilation

design. Jet fans

are used for

road tunnel

ventilations to

push the air in

different

scenarios.

Traffic

situation and

firing mode are

the sensitive

parameters. The

firing mode is

the critical

mode that is

considered for

road tunnel

ventilation

design. Using

CFD simulations

the most

effective

scenarios for

jet fan

operating in

firing mode in

different

locations of the

tunnel and

taking into

account the

various

parameters such

as the slope of

the highway is

achievable. In

this project a

firing source

term was created

in different

locations and

the effect of

different

arrangements,

scenarios and

jet fan power on

smoke

ventilation was

widely studied.

Based on

researches a

deep insight

into road tunnel

ventilation

design was

produced in Arya

Alborz

engineering

group.

|

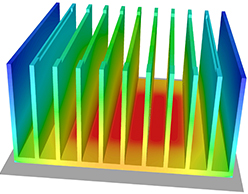

3D

Numerical

Simulation of

Heat Transfer in

a p4 CPU Heat

Sink

This project is

performed in

2002 with the

aim of heat sink

cooling design

knowledge

reverse

engineering.

Geometric

parameters of

heat sink and

CPU loading are

some of the

sensitive

factors that

were reviewed.

CPU heat source

is exerted to

the simulation

as a boundary

condition at the

bottom of heat

sink. Using CFD

simulation the

effect of CPU

load, heat sink

design and fan

power was

studied and a

good insight for

electronic

device cooling

was provided in

Arya Alborz

Company.

|

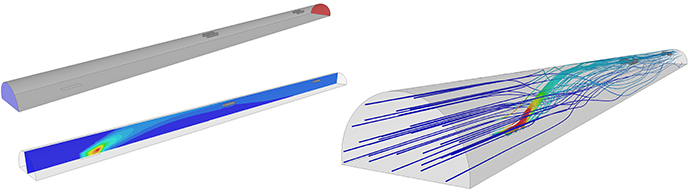

Comprehensive CFD Simulation

of an Ejector

for Exhaust

Cooling

This project was

performed in

2013 to develop

the knowledge of

ejector design

for exhaust

cooling using

numerical

simulations.

Ejectors can be

used in various

industries for

hot gas cooling.

In this

technique hot

fluid passes

through narrow

holes and sudden

pressure drop

reduces the

temperature.

Besides

producing high

speed gases

inside the

chamber,

reduction in

static pressure

can vacuum the

fresh air that

can be mixed

with hot exhaust

and eventually

the performance

can be

increased.

Reverse

engineering

process was

executed on an

ejector. At the

first step a 3D

model was

created. After

mesh generation,

comprehensive

thermo-flow

analyses using CFD simulations

were performed.

Based on the

studies, the

effect of

various

geometric and

operating

parameters on

cooling

performance was

specified and

was validated

with

experimental

tests. In this

project a deep

insight into

ejector design

for all

industries was

produced in Arya

Alborz Company.

|

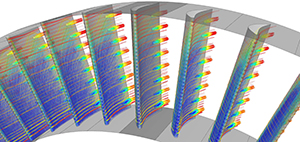

Primary

Simulation of

j-85 Blade

Cooling Using CFD Simulations

This Project was

performed in

2009 with the

aim of design

review of stator

blade cooling

strategies using

CFD simulations.

Film cooling and

convective

cooling are the

two main

strategies for

rotating

equipment blade

cooling. In

convective

cooling the

holes are placed

close to the

trailing edge.

In this

technique the

coolant air

enters from the

root of the

blades and after

passing through

the baffles,

absorbs the

blade heat and

exits. In film

cooling

technique the

coolant air

flows through

the baffles and

exits from the

holes placed at

the leading

edge. Coolant

air flows from

leading edge

holes leads the

formation of a

cooling film on

the blade and

eventually

reduction in

direct contact

of combustor hot

gas with blades

surface. Due to

stress

dependence to

temperature,

cooling can help

the design and

equipment life

extension. Using

CFD simulation

the optimum

design of

internal baffle

was also

studied.

Internal baffles

design can

change the

percentage of

coolant air

distribution

through trailing

edge or leading

edge. Using

comprehensive

CFD simulations,

the effect of

film cooling on

flow angle and

rotor torque was

also specified.

This project has

produced a deep

insight into the

blade cooling

design of

rotating

equipments in

Arya Alborz

Company. In

picture below

the flow

patterns in

stator stage

without any

baffle is

presented.

|

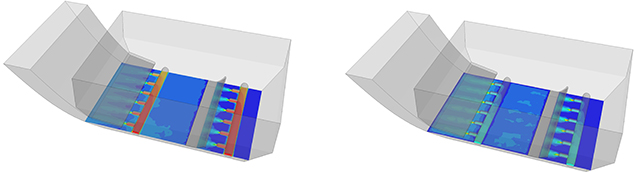

Simulation and

Optimization of

Uniform Hot Jet

Using CFD

Techniques

This project was

performed in

2011 with the

aim of uniform

hot jet creation

for food

industry. Heat

can penetrate to

the center of

the dough in

bread cooking,

using hot jet

system. Using a

uniform hot jet

can lead to a

proper baking.

At first step a

3D model was

created for

primary

analysis. Then

after mesh

generation and

fluid flow

simulations,

baffles were

designed to

produce a

uniform hot jet

for bread

cooking.

|