|

Heat

Exchangers

Redesigning the

Heat Exchanger

of an Electric

Motor Using CFD

Simulation.

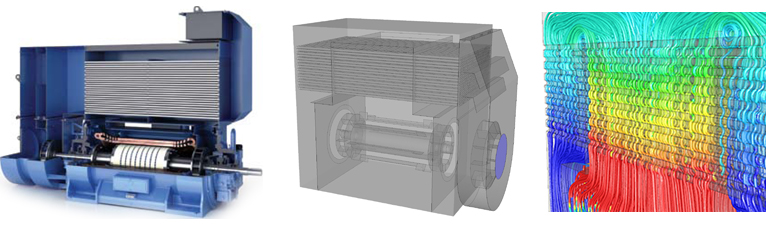

This project was

performed in

2013 with the

aim of

optimizing the

heat exchanger

of a 2MW three

phase induction

electric motor

of Hitachi

Company for full

load operation

during summer.

In this project

the geometrical

characteristics

such as the size

of the rotor,

stator, inner

ducts and the

cold and hot

streams of the

heat exchanger

were extracted.

After creating a

complete

geometric model

of the engine

and a very

complex 34

million mesh

generation,

fluid and heat

analysis inside

the electric

motor and the

heat exchanger

with the use of

high-speed

computers was

performed.

After the

specification of

temperature

distribution in

electric motor

and heat

exchanger, the

heat exchanger

with the aim of

modifying the

cooling system

was optimized.

|

Optimization of

a 1960 Tubes

Compact Air to

Air C-130

Airplane Heat

Exchanger Using CFD Simulation.

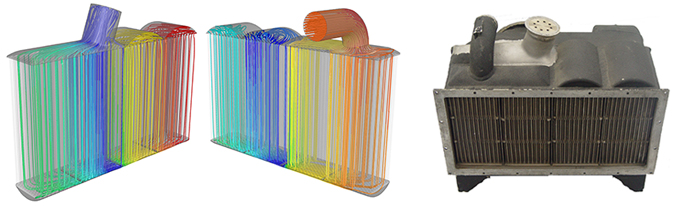

This project was

performed in

2006 with the

aim of

optimization and

modification of

the heat

exchanger. This

heat exchanger

is used for

cabin

ventilation of

C-130 airplane.

The hot

compressed air

in engine is

cooled by the

cold fresh air

at high

altitudes in a

four pass heat

exchanger.

With

mathematical

analyses and CFD

simulations,

optimization for

improving the

thermal

efficiency of

the heat

exchanger was

achieved.

|

Inlet

Manifold

Optimization of

a 1800 Tubes

Compact Air to

Air C-130

Airplane Heat

Exchanger Using CFD Simulation.

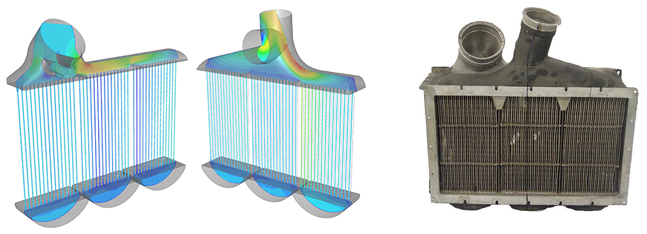

This project was

performed in

2006 with the

aim of inlet

manifold

optimization to

fix the problem

of flow

maldistribution

and hot spot

reduction. This

heat exchanger

is used for

cargo

ventilation of

C-130 airplane.

The hot

compressed air

in the engine is

cooled by the

cold fresh air

at high

altitudes in a

two pass heat

exchanger.

The destruction

of connections

between intake

manifold and

tubes because of

the hot spots,

caused the

leakage and

problem in

cooling and

adjusting the

pressure at high

altitudes inside

the cargo

compartment.

Using CFD

simulations, new

manifold with

uniform flow and

temperature

distribution,

higher thermal

efficiency and

longer life was

designed.

|

Shell and

Tube Heat

Exchanger

Optimization

Using CFD

Simulation.

This

investigation

has been started

in Arya Alborz

Company since

2008 with the

aim of shell and

tube heat

exchangers

optimization. In

this project

comprehensive

studies on the

shell and tube

heat exchangers

were performed

to identify

various

optimization

techniques of j

factor and f

factor. After

the study of

segmental baffle

shell and tube

heat exchangers,

optimization

with the use of

Helical baffle

design (Helixchangers)

for higher

thermal

efficiency and

fouling

reduction was

developed. Based

on comprehensive

CFD simulations,

lower pressure

drop can lead to

design a heat

exchanger with

higher thermal

efficiency. Also

reduction in

fouling and two

or three times

life extension

with higher

thermal

efficiency are

the benefits of

Helixchangers

compared to

segmental baffle

shell and tube

heat exchangers.

|