|

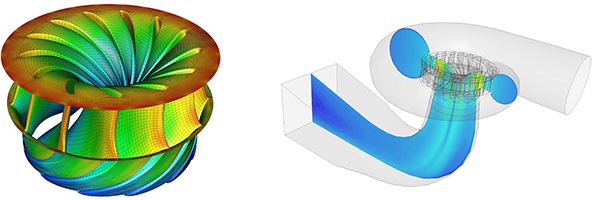

Rotating Equipments

Comprehensive CFD Simulation

of a 260 MW

Pump-Turbine in

Pump Mode

Operation.

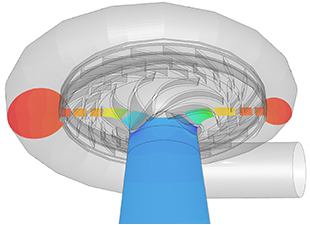

This project was

performed in

2011 to identify

the effect of

geometric

variations and

operational

conditions on

hydraulic

performance with

the aim of

reverse

engineering. Atos 3D scanning

equipment was

used to create a

precise cloud

point of runner.

Using the

drawings, the 3d

geometries of

spiral case,

stay vanes,

guide vanes,

draft tube and a

complete model

of hydraulic

pump was

created. After a

professional

structured mesh

generation for

runner, spiral

case and draft

tube, the effect

of operating

conditions on

hydraulic

efficiency,

head, runner

torque,

cavitaion and

other parameters

were studied.

Because of

discrepancy in

runner geometry

between model

test and

prototype, the

effects on

hydraulic

parameters and

power plant

efficiency was

comprehensively

studied.

|

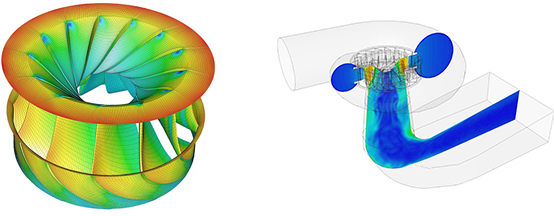

Comprehensive CFD Simulation

of a 260 MW

Pump-Turbine in

Turbine Mode

Operation

This project was

performed to

identify the

effect of the

geometric

variations and

operational

conditions on

the hydraulic

performance with

the aim of

reverse

engineering in

2011. Atos 3D

scanning

equipment was

used to create a

precise cloud

point of runner.

Using the

drawings, the 3d

geometry of

spiral case,

stay vanes,

guide vanes,

draft tube and a

complete model

of hydraulic

turbine is

created. After a

professional

structured mesh

generation for

runner, spiral

case and draft

tube, the effect

of operating

conditions on

hydraulic

efficiency,

head, runner

torque,

cavitaion and

other parameters

were studied.

Because of

discrepancy in

runner geometry

between model

test and

prototype, the

effects on

hydraulic

parameters and

power plant

efficiency were

comprehensively

studied.

|

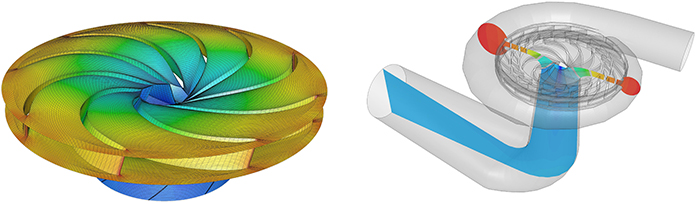

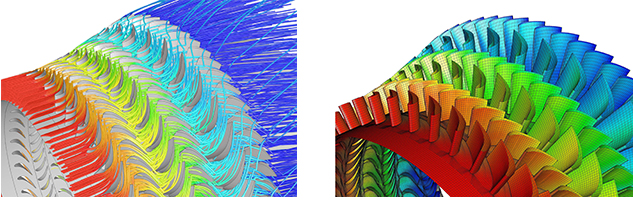

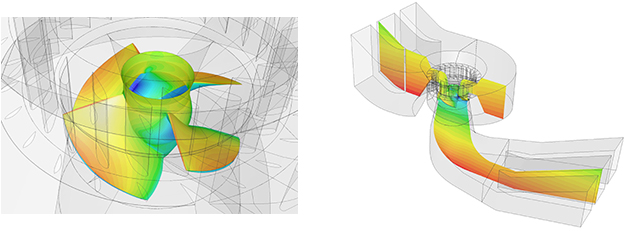

Comprehensive CFD and FEM

Simulation of a

Three Stages 4

MW Solar Centaur

Gas Turbine

This project was

executed in 2009

to identify the

potential of

improvements.

Atos 3D scanning

equipment was

used to create a

precise cloud

point of three

stages rotor and

stator. Using

cloud points, a

complete solid

model of a three

stages gas

turbine

including two

stages

compressor

turbine and one

stage power

turbine was

created.

Compressor

turbine and

power turbine

have different

shafts and

rotational

speeds. After

structured mesh

generation with

fine elements

for precise

boundary layer

simulation,

fluid flow and

heat transfer

were studied for

the entire of

three stages

turbine. Because

of difference in

the number of

blades in rotor

and stator of

three stages and

the

impossibility of

producing a

periodic sector,

regardless of

any

simplification

and assumptions

the CFD

simulations were

executed for the

entire domain

using parallel

high speed

computers. Using

pressure and

temperature

distribution on

blades, non

linear FEM

simulations to

study the Von

Mises stresses

on three stages

of rotor and

stator were

executed. After

a comprehensive

analyses of the

turbine using

CFD and FEM

simulations,

different

scenarios for

optimization

were widely

studied.

|

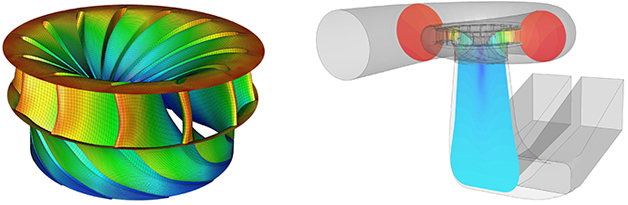

Comprehensive CFD and FEM

Simulation of a

250 MW Francis

Turbine

This project was

performed with

the aim of

reverse

engineering in

hydraulic

Francis turbine

design in 2008.

Atos 3D scanning

equipment was

used to create a

precise cloud

point of runner.

Using the

drawings, the 3d

geometry of

spiral case,

stay vanes,

guide vanes,

draft tube and a

complete model

of hydraulic

turbine was

created. After a

professional

structured mesh

generation for

runner, spiral

case and draft

tube, the effect

of operating

conditions on

hydraulic

efficiency,

head, runner

torque,

cavitaion and

other parameters

were studied.

After a

comprehensive

simulation of

hydraulic

turbine, the

effect of some

geometric

optimization

such as draft

tube length

reduction on

hydraulic

efficiency and

power plant

operation was

carried out.

|

Comprehensive CFD and FEM

Simulation of a

250 MW Francis

Turbine with

X-Blade Design

This project was

performed in

2008 with the

aim of reverse

engineering in

hydraulic

Francis X-blade

turbine design

and geometric

optimization of

runner to fix

the cracks and

the effects on

power plant

hydraulic

efficiency. Atos

3D scanning

equipment was

used to create a

precise cloud

point of runner.

Using the

drawings, the 3d

geometry of

spiral case,

stay vanes,

guide vanes,

draft tube and a

complete model

of hydraulic

turbine was

created. Due to

cracks growing

on runner

blades, CFD

simulations for

Speed no load

and Load

rejection

condition were

also studied.

The pressure

distribution on

runner blade for

different

conditions were

used for FEM

analysis. After

designing

failure

detection,

various

modifications on

blade profiles

and thicknesses

were carried out

using coupled

CFD and FEM

simulations.

Finally the best

runner with high

hydraulic

performance and

sufficient

strength was

designed.

|

Comprehensive CFD and FEM

Simulation of a

8 MW Francis

Turbine

This project was

performed in

2010 with the

aim of reverse

engineering in

hydraulic

Francis turbine

design and

benchmarking for

small hydraulic

power plant

potentials in

country. Atos 3D

scanning

equipment was

used to create a

precise cloud

point of runner.

Using the

drawings, the 3d

geometry of

spiral case,

stay vanes,

guide vanes,

draft tube and a

complete model

of hydraulic

turbine was

created. After a

professional

structured mesh

generation for

runner and draft

tube, the effect

of operating

conditions on

hydraulic

efficiency,

head, runner

torque,

cavitaion and

other parameters

were studied.

Based on CFD

results, the

pressure

distribution on

runner was used

for

comprehensive

FEM simulations.

|

Comprehensive CFD Simulation

of a 100 MW

Kaplan Turbine

This project was

performed in

2010 with the

aim of reverse

engineering in

Kaplan hydraulic

turbine design.

Using the

drawings, the 3d

geometry of

spiral case,

stay vanes,

guide vanes,

draft tube,

runner and a

complete model

of hydraulic

turbine was

created. After a

professional

structured mesh

generation for

spiral case and

draft tube, the

effect of

operating

conditions on

hydraulic

efficiency,

head, runner

torque,

cavitaion and

other parameters

were studied.

|

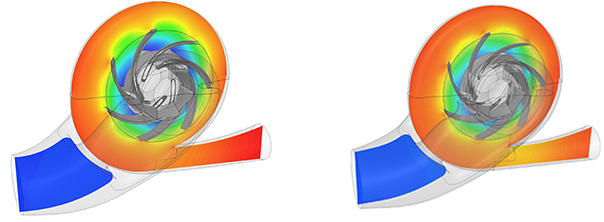

Comprehensive CFD Simulation

of Two BB1 API

610 hydraulic

pumps

This project was

performed in

2012 with the

aim of

evaluating the

efficiency of

two hydraulic

pumps. After the

identification

of reasons for

the lower

efficiency in

one of them,

some innovative

techniques for

optimization on

both of them

were found out.

Atos 3D scanning

equipment was

used to create a

precise cloud

point of two

impellers and

volutes. Then

complete models

of two hydraulic

pumps were

created. After a

professional

structured mesh

generation for

impellers with

boundary layer

growth, CFD

simulations were

executed.

Because of 10%

lower head in

one of the

pumps, losses at

different

sections were

compared.

According to the

results,

critical

sections were

found out so

that with lowest

geometric

modifications of

molds, the most

effectiveness on

hydraulic

efficiency was

achieved.

|

Comprehensive CFD Simulation

of Wind Farm

Considering the

Wake Effect of

Upstream

Turbines

These studies

were performed

with the aim of

producing a deep

insight into the

design of wind

farms and wake

effect of

upstream

turbines on

plant

efficiency. In

this study a

domain with two

200 KW wind

turbines were

simulated. The

second turbine

was placed in

different

locations

compare to the

first turbine to

study the wake

effect.

Comprehensive

CFD simulations

at different

wind speeds and

wind turbine

rotational

speeds were

performed and

torque and power

were widely

studied. Due to

the significant

reduction in

power generated

in the

downstream

turbines,

producing

software for

optimum wind

farms design

with the

consideration of

wake effects has

been started in

Arya Alborz

Company.

|